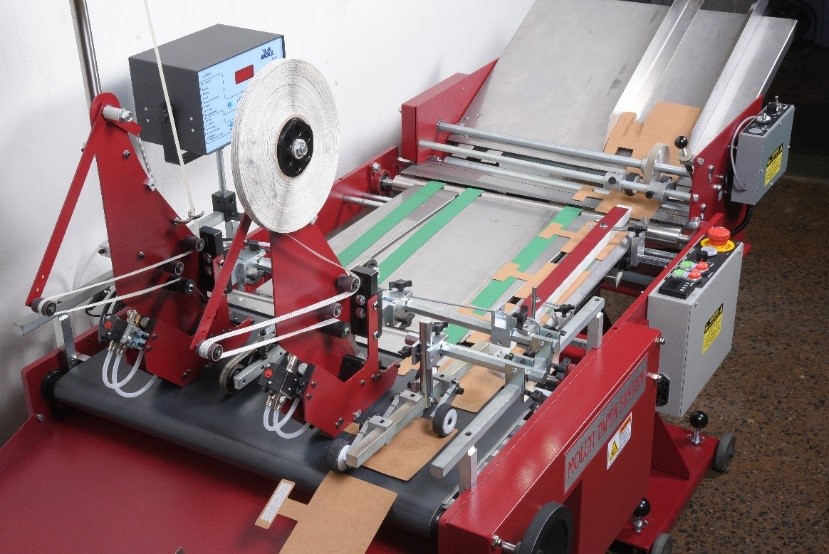

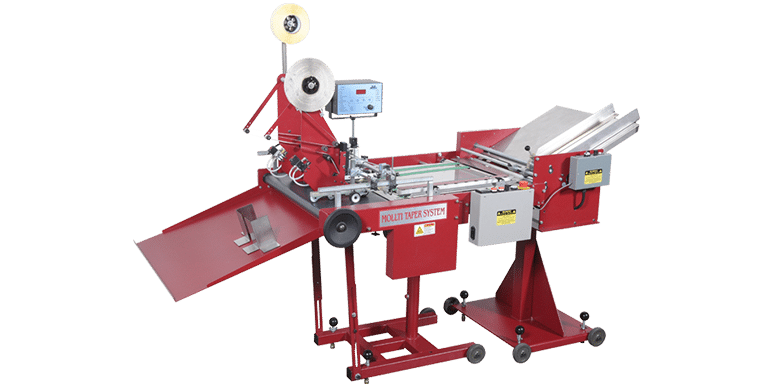

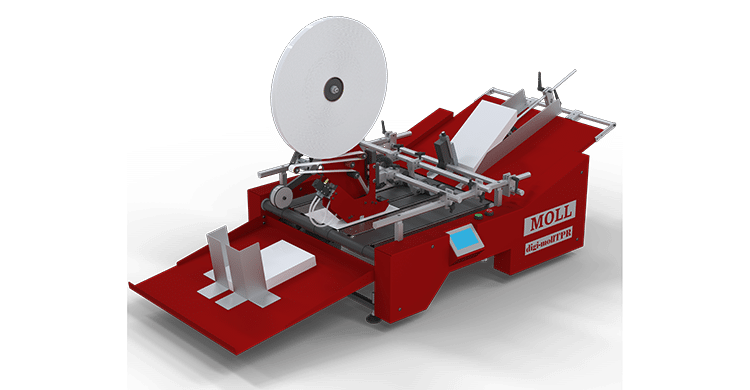

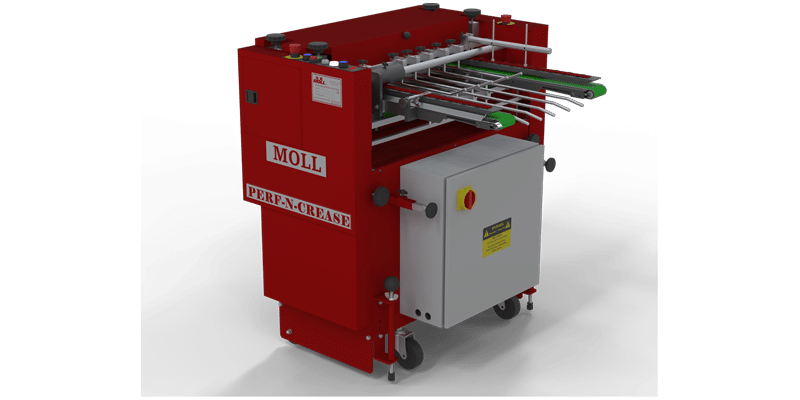

Moll FlexCut 102 Digital Rotary Die Cutter System

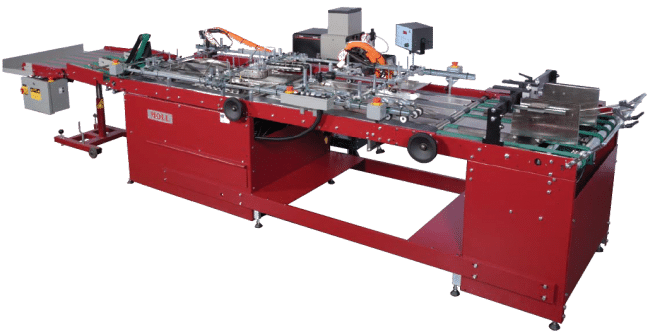

B&R Moll introduces their in-line, sheet-fed, flaxo magnetic rotary die cutter, folder/gluer system

The MOLL die cutter, folder gluer creates a distinct position in the Label, Mail, Printing, and Packaging Markets for sheet-fed applications. It will also kiss cut and cut-score products in an infinite number of shapes and sizes including substrate thicknesses up to 24pt paperboard. It’s ideal for finishing boxes, cartons, labels, pocket folders, and other types of packaging.

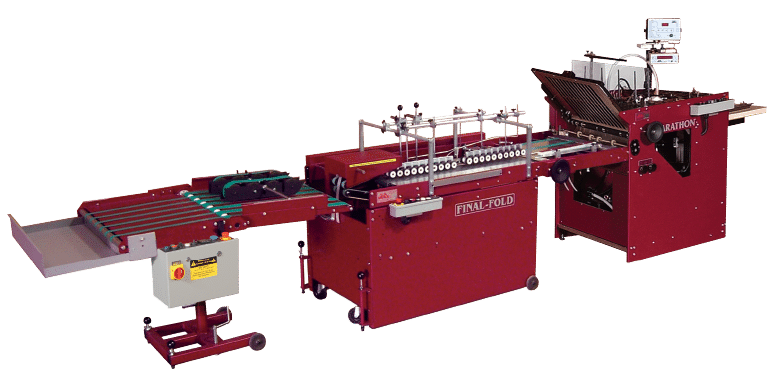

You can run the Moll Die Cutter System’ work from the Stripping Unit, into Moll’s Versa-Fold and Dial-A-Stack for die cutting, stripping, folding, gluing, and finishing in-line! Through the integration of Moll’s Die Cutter and Folding/Gluing equipment you are making a 4 step process a 1 step process, reducing time, labor, and ultimately leading to more profit for your company.

Features

- Touch screen controls

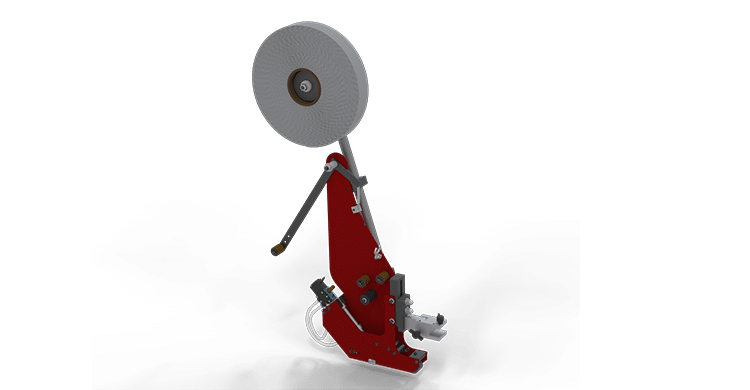

- Top air suction feed w/ adjustable sucker heads with adjustable front air separation blower

- Servo driver pre-registration

- Nickless die cutting

- Positive die register in the operator side

- Sheet count and batch control monitors

- Off-site maintenance and troubleshooting capabilities

- Mechanical double-sheet detector

- Digital Print to cut registration and lead edge cut registration

- Servo driven registration – Gripper – less

- One servo driven infeed nip to drive and register sheets into the die cutter

- Dual magnetic cylinders which houses magnetic flexible die

- Micro Gap die control in 0.0001 increments

- Spherical roller bearings class 3 – Sealed for life

- Direct vertical cylinder loading – the sheets of paper stay flat while traveling through machine

- Run speeds up to 5,000 sheets per hour w/ variable speed adjustment

- Jam detector at the matrix diverter

- One no-sheet detector after die nip, which will shut down machine if sheet, is missing after going through die nip

- Stripping section that deflects the matrix waste down

- Pallet feeder for easy loading

Types of Cutting

Die Cutting, kiss cutting, scoring, slitting, and perfing

Industries/Consumers served

Food/beverage, games, greeting cards, business cards, health care, POP, pharmaceutical, accounting/financial institutions, commercial print, and more!

Specifications

| Imperial | Metric | |

| Minimum Sheet Size | 8.5 x 11 inches | 215 x 279 mm |

| Maximum Sheet Size | 30″W x 40″L | 760 mm x 1020mm |

| Minimum paper Substrate Thickness | 8 pt | 190gsm / 260 microns |

| Maximum paper Substrate Thickness: | 24pt | 454gsm / 610 microns |

| Product Speed | 5,000 sph | 5,000 sph |

| Electric | 220V, 3PH, 30AMP, 60 HZ | 400V, 3PH, 30AMP, 50 HZ |

| Air | 90 PSI | .7 mPa |

Options

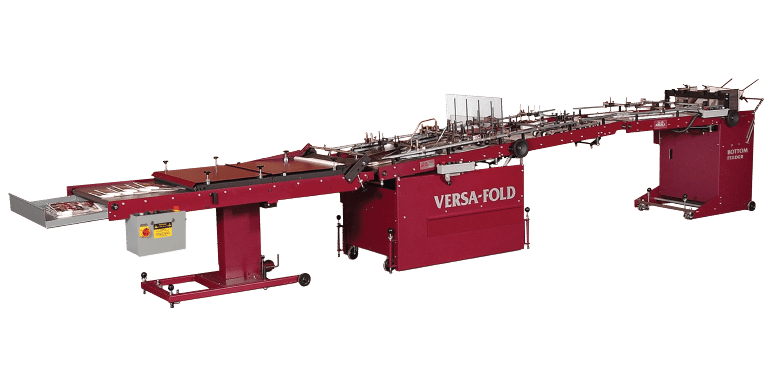

- Versafold

- Extended Stacker

- Cold Glue System

- Hot Glue System

- Receding Stacker